One of the UK’s leading specialists in robotic 3D printing systems will lead the manufacturing element of a new £700,000 project to transform maritime vessel design and production.

Rapid Fusion, which develops advanced production solutions from its R&D centre in Exeter, will join forces with Compute Maritime and consortium partners BYD Naval Architects, Siemens Digital Industries Software and the University of Southampton on the Clean Maritime Demonstration Competition initiative funded by the UK government.

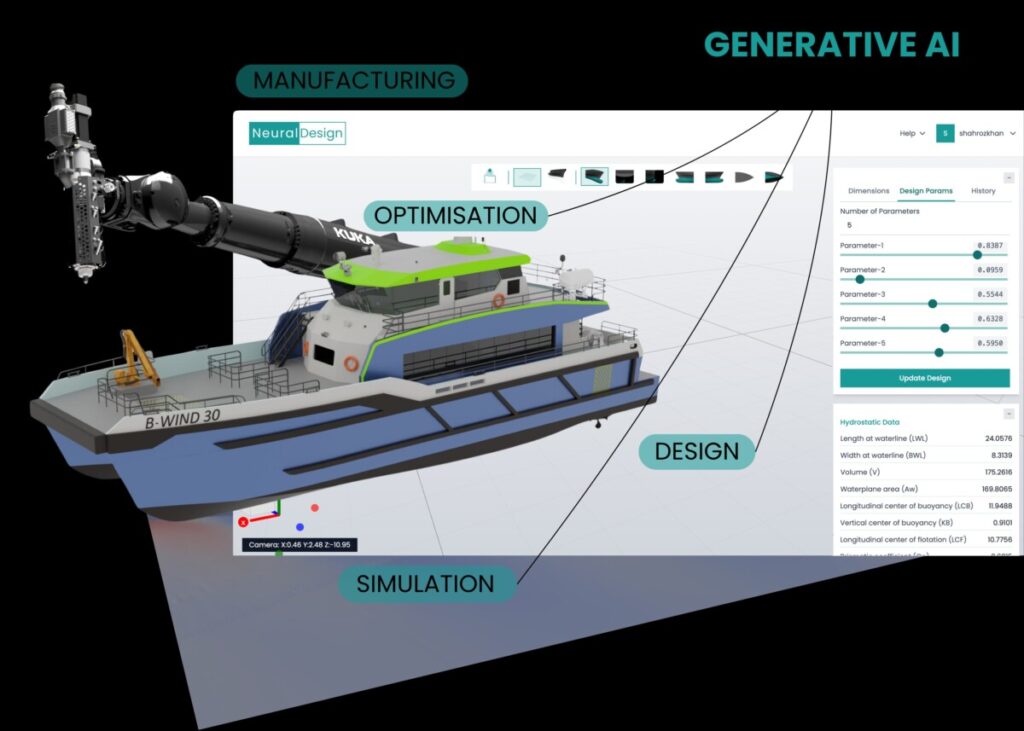

Together, the core innovation of ‘GenDSOM’ will be to advance maritime design by leveraging generative artificial intelligence (AI)-driven approaches and building foundation models, thereby significantly reducing the design-to-manufacturing cycle and enabling high-performing, innovative solutions.

This will be achieved by embedding greater intelligence into modern design through the combination of simulation, optimisation, and validation against real-world manufacturing constraints and workflows.

The approach brings together the complementary expertise of the consortium partners: generative AI (Compute Maritime), design (BYD Naval Architects), simulation (Siemens), optimisation (University of Southampton) and manufacturing (Rapid Fusion).

This integrated development will be powered by the advanced compute capabilities of HP Z Workstations & Solutions.

A crew transfer vessel (CTV) provided by BYD Naval Architects – critical to supplying staff to the offshore wind sector – will be the test case and focuses on optimising hull design with hydrofoils produced in large format additive manufacturing using Rapid Fusion’s Apollo robot system.

“Confronted by multifaceted challenges, the maritime industry urgently requires truly evolved, smart design frameworks that balance sustainability with operational and economic viability,” explained Shahroz Khan, CEO of Compute Maritime, a London-based deep-tech company bringing intelligence to the core of the global shipbuilding industry.

“The transformation of ship design is no longer optional – it is a critical survival strategy in an industry historically anchored in tradition. That’s why this project is so important, and we firmly believe that through the power of NeuralShipper (our generative AI copilot) and the expertise of our consortium partners we can achieve a 10% reduction in design costs, 20% faster design cycles, and a 50% increase in overall design efficiency.”

He went on to add: “GenDSOM responds directly to the UK’s 2025 Maritime Decarbonisation Strategy, which targets emissions reductions of 30% by 2030 and 80% by 2040 for domestic maritime. As highlighted in the Call for Evidence, decarbonising smaller vessels like CTVs is critical to achieving these targets.”

Rapid Fusion has been chosen for its expertise in Large Format Additive Manufacturing (LFAM) and will be using ‘Apollo’, a full turnkey 3D printing solution that utilises the power of robotics to support the production of large components and moulds

.

It was the company’s first robotic cell to be launched and offers faster speeds than FDM printers (nearly 200 times quicker), as well as the ability to use hundreds of different engineering-grades polymers whilst achieving custom composites.

Clients also have the potential to secure significant cost savings as pellets can cost 65% to 90% less than filament of the same plastic.

Martin Jewell, Chief Technical Officer at Rapid Fusion, commented: “Additive manufacturing has expanded design freedoms and is rapidly gaining traction for both small components and large structures, including hull forms, in the world of maritime.

“Yet scalability remains constrained. GenDSOM is going to adopt a modular strategy, breaking designs into manufacturable subcomponents compatible with both traditional and AM processes.

“Our manufacturing-aware approach ensures designs remains manufacturable while integrating constraints, building envelope limits, support structures, tolerance stacking and material compatibility for instance. All of this will ensure innovative, efficient, and production-ready solutions, while enabling decarbonisation across the design-to-manufacturing lifecycle.”

Set to take place over the next seven months, the Innovate-backed project brings together the expertise of Siemens Digital Industries, the research of the University of Southampton, and the team of BYD Naval Architects.

Whilst not an official partner yet, Compute Maritime will also be tapping into the compute power of HP Z Workstations to train AI models locally rather than in the cloud, giving it more control over energy consumption and sourcing.

Shahroz Khan concluded: “We are really pleased to have Rapid Fusion on board for the manufacturing element of the project.

“It has a proven track record in pushing the boundaries of innovation whilst acknowledging the manufacturing constraints of what is possible – this will be critical in delivering what we believe will be an important breakthrough for the maritime world.”

The GenDSOM is funded by UK government through the UK Shipping Office for Reducing Emissions (UK SHORE) programme in the Department for Transport. Innovate UK, part of UK Research and Innovation, is the main delivery partner for UK SHORE interventions.

Consortium partners also commented:

Dmitry Ponkratov, Marine Director at Siemens Digital Industries Software: “This project represents a new leap within maritime design. Bringing all the digital elements within one loop will unlock a new paradigm of convergence, where design, performance, and manufacturability evolve simultaneously – not sequentially.

“We are excited to partner with the other members, especially Rapid Fusion, to bring manufacturing capability into the preliminary stage of design. This ensures designs are developed with awareness of the constraints that typically only emerge later in the detailed stage.”

Jami Buckley, CEO of BYD Naval Architects: “GenDSOM will have a unique ability to generate solutions that would otherwise be difficult, if not impossible, for designers relying solely on domain expertise or incomplete problem definitions. Such scenarios often arise in specialised projects adopting next-generation propulsion technologies or alternative fuels.”

Tashin Tezdogan, Professor at the University of Southampton: “Whilst retrofitting with emission-reduction technologies provides incremental benefits, the largest fuel savings come from optimising vessel form and components.

“Historically, vessel design progress was constrained by limited tools and evaluation methods. Today, intelligent tools like NeuralShipper can generate highly efficient, unconventional hull shapes, supported by advanced simulations that accurately assess performance. GenDSOM therefore aims to address the core challenge of designing more efficient vessels.”

For further information, please visit www.rapidfusion.co.uk/ and https://www.computemaritime.com/.